May 24, 2022

What Is A Laser-Cut Key?

Have you heard the term 'laser cut key' or wondered what makes one key different from another? If so, then read on. You've come to the right place. Things can get a little technical when we talk about locks and keys. But you don't need to worry. Here at Diego's Locksmith, we want to make everything as simple as possible for you.

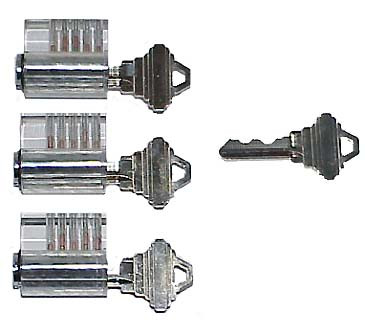

Laser-cut keys are among the newest and most advanced methods of creating a key. The laser-cut key is made by cutting through steel, brass, or aluminum with a laser beam, and this produces a clean-cut key with no burrs or rough edges. These keys can also be customized with various finishes, such as anodized, satin nickel, and polished brass.

The laser-cut key process produces high temperatures in the metal that melt it into the desired shape before cooling down again and hardening it into place. The process is similar to using a 3D printer, except instead of printing an object from plastic or another material, it uses heat to melt metal into its final shape.

The process starts with a blank key, then cut using an industrial laser. After the cutting process is complete, the key blank is then drilled for use in your lock cylinder. This allows for more intricate and more complex keys to replicate than those created with traditional methods.

How Is A Laser-Cut Key Different From a Traditional Key?

A traditional key comprises two pieces: the head and the shaft (or bow). The head slides into a lock and turns to open it; the shaft remains outside the lock and can be used as an "emergency" unlocking tool if you lose your keys or if someone tries to pick your lock.

A laser-cut key has only one piece, so it cannot be picked or duplicated without destroying it first. It also makes it stronger than its traditional counterpart, meaning that it will last longer before you need a key replacement.

Benefits of a Laser-Cut Key

There are many benefits to using a laser-cut key instead of traditional locksmith methods. One of the main benefits is that it is faster and easier than traditional cutting keys. In addition, it requires less skill to use the equipment than other methods, so that anyone can do it with minimal training. Another benefit is that the keys are more durable and last longer than traditional ones because they are not easily worn down by normal use, such as opening doors or repeatedly using them in locks.

Laser-cut keys are cheaper to produce many keys at once than if you were to produce each one individually by hand or even with another machine. The cost savings come from the fact that there are no materials wasted during production since all pieces are exactly alike from start to finish, and there are no leftovers from previous jobs when starting new ones. There is no need for extra inventory after each production run since every piece produced is identical.

Diego's Locksmith For Your Laser-Cut Key Needs

A lock is only as secure as the key that opens it. Without a quality key, getting back inside your home or business may be challenging. But with Diego's Locksmiths, we can fabricate a new key that's cut to fit your unique lock.

Thank you for calling Diego's Locksmith.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)